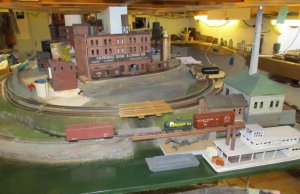

Eastern Tn logging on the DG CC & W RR 1928

- Thread starter Bill Nelson

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks nevadablue. I like to post step by step progress, this current rebuild is a massive job, but it is taking shape bit by bit,

have been cleaning my aisles, and cleaning my work bench, as well as doing some benchwork carpentry in the vicinity of the new log transfer off the narrow gauge, which is as yet un named ( possibilities under consideration are Sunburst, Skybridge, Snowbird, and a few others, not really satisfied, so I'm open to suggestions. I'm using some elements from the old Terrapin log loading area, but the name Terrapin has properly ben assigned to the return loop at the far end of the system; which fit the Grateful Dead lyrics from the song Terrapin Station "Terrapin, I can't figure out, Terrapin, if it's the end or beginning."

In any case on the work bench partially buried was a Ma & Pa 2-8-0 I've been struggling with motor issues. I removed the original motor and tried two others one was too fast and too noisy, the other was too slow and too noisy. I bought a handful of NWSL 1225D-9 motors to redo all my AHM 4-4-0s and 2-4-0s in the hope that they will run beter, and that with the same motors, and gearing, they might be available to run in pairs to hump some trains up the mountain. I had been working on trying to fit one of the little motors in the 2-8-0, and had been fighting the drastic size difference in the motor shaft and the input shaft on the locomotive I finally wollowed out the end of a universal from micro-mark to get it to press fit on the input shaft. I had a short piece of tubing from a pediatric central line extension, which fit snugly on the motor shaft. a piece of tubing, perhaps from a nebulizer, fit snugly on that. that was just a tad loose in the end of the universal, so I but a small piece of heatshrink tubing on the nebulizer line, and the other end of the universal fit snugly.

I need to do more work on the electrical system. i had built a pick up for the middle two insulated drivers, bur unwisely mounted it on the gear box. the gearbox can rotate some on the axle so that was not a good place for it. I broke it off wile working on trying several motors out. this motor, while a tad small, provides a decent slow speed, a quite good maximum speed, and isn't Quite as loud as some of the others I have tried. for some reason this locomotive seems to be a growler.

It is , however a handsome locomotive, as almost all Baldwins are. it does not have a number or an assigned duty yet. as my rebuild gets a bit farther on, I hope to get a better handle on what the operational needs of the system will be.

Nelson

In any case on the work bench partially buried was a Ma & Pa 2-8-0 I've been struggling with motor issues. I removed the original motor and tried two others one was too fast and too noisy, the other was too slow and too noisy. I bought a handful of NWSL 1225D-9 motors to redo all my AHM 4-4-0s and 2-4-0s in the hope that they will run beter, and that with the same motors, and gearing, they might be available to run in pairs to hump some trains up the mountain. I had been working on trying to fit one of the little motors in the 2-8-0, and had been fighting the drastic size difference in the motor shaft and the input shaft on the locomotive I finally wollowed out the end of a universal from micro-mark to get it to press fit on the input shaft. I had a short piece of tubing from a pediatric central line extension, which fit snugly on the motor shaft. a piece of tubing, perhaps from a nebulizer, fit snugly on that. that was just a tad loose in the end of the universal, so I but a small piece of heatshrink tubing on the nebulizer line, and the other end of the universal fit snugly.

I need to do more work on the electrical system. i had built a pick up for the middle two insulated drivers, bur unwisely mounted it on the gear box. the gearbox can rotate some on the axle so that was not a good place for it. I broke it off wile working on trying several motors out. this motor, while a tad small, provides a decent slow speed, a quite good maximum speed, and isn't Quite as loud as some of the others I have tried. for some reason this locomotive seems to be a growler.

It is , however a handsome locomotive, as almost all Baldwins are. it does not have a number or an assigned duty yet. as my rebuild gets a bit farther on, I hope to get a better handle on what the operational needs of the system will be.

Nelson

I built up some of the support for the walk under, where the narrow gauge will cross over the aisle at the walkunder on the south wall of the RR room. I doubled up some 5/8ths inch plywood. which is fastened to the benchwork, and braced with boards running between the risers where the upper decks benchwork is split into two sections, in case it ever needs to be removed from the room. the upper deck is super solid lengthwise here, but has some movement right to left. I'm going to use 5/8th plywood for sub roadbed on the walk under. and brace the shelf it comes off of thoroughly against the south wall, and the west sloped ceiling, and hopefully this will help stabilize the side to side movement of the upper deck here. I was setting up the log loader for the standard gauge at the log transfer here, and discovered I was about to make a big mistake. I was using the log loader platform salvaged from Terrapin, and was planning on using it as is. That won't work. with the 8.5% grades I had, log trains were 4 or five cars long, and the loading platform was built accordingly. With the current rebuilds much gentler grades I may be able to run 8 car log trains, and I need to do some surgery to the loading platform, splicing some of the log bridge on the front side to the tail track, so the tail track can accommodate longer trains.

the narrow gauge will run along the right side of a ridge. the sting shows the level of the underside of the narrow gauge's roadbed. it will cross over the tail tracks to the wye, and the log loading siding just to the right of the massive support on a curved trestle . the ridgeline will block the view of the narrow gauge main line from the aisle to the left, but there will be some narrow gauge tracks coming down to the log reload, that will be visible from the left. Designing this mess was one of the biggest problems on my redesign, accommodating the standard gauge main, the narrow gauge main. the wye, and the log reload off the narrow gauge without looking too crowded. I will have to make considerable progress before I can figure out if I pulled it off.

the narrow gauge will run along the right side of a ridge. the sting shows the level of the underside of the narrow gauge's roadbed. it will cross over the tail tracks to the wye, and the log loading siding just to the right of the massive support on a curved trestle . the ridgeline will block the view of the narrow gauge main line from the aisle to the left, but there will be some narrow gauge tracks coming down to the log reload, that will be visible from the left. Designing this mess was one of the biggest problems on my redesign, accommodating the standard gauge main, the narrow gauge main. the wye, and the log reload off the narrow gauge without looking too crowded. I will have to make considerable progress before I can figure out if I pulled it off.

last week I traded some of my dad's On3 stuff for some old timey Ho cars a Mantua ventilated boxcar, and two AHM truss rod box cars. they have been through the shops, the car to the left has been in service for close to 40 years , and I tried to match the look. these older home service cars will likely be in service between the company store for the Berghausen -Shoemaker Lumber company and the log camps supplying the loggers in the woods. I'm extremely happy with these cars. Proto 2000 33 inch smooth backes wheel sets fit the AHM car's trucks perfectly. next time I'm making resin castings, I'm set up to make a mould for the AHM kingpins , ( I an missing quite a few) and if I had a good replace ment I could return a lot of these cars to service.

The other day I had the log loading rack from old Terrapin set up in the new, as of yet un named log reload area off the narrow gauge. I was thinking (not really the right word) that I could use it as is, and then I realized that with my old 8.5% grades a four car train was the norm. With an 3.3% ruling grade on the main, and a slightly steeper grade on the lead to the loading track, 8 car log trains may be possible, so room for four cars behind the loader would cause a major bottle neck, and some un necessary switching, in an area on the layout that will be too busy as is. so I cut some of the log bridge deck off the front of the assembly, and spliced it onto the back. I will run the back end of the cribbed loading deck, back to ground level, and add a short section of roadbed to allow another two or three extra cars , hopefully I'll be able to deal with loading a log log train big enough to make the new layout work, without Jacking up the Gizzard block with unnecessary switching.

Ready to cut the loading deck

ready to splice the loading deck bridge

One of The The Surry Parker will sit on the planked area, the short end is the lead to the rest of the siding, and the long lead will hold empty log cars that have passed under the Surry Parker .

this close up shows the rough edges you get separating Midwest cork roadbed. That rough edge can cause problems when ballasting, causing a rough edge, or worse, voids in the ballast just below those rough edges. I have found I get a lot better looking roadbed if I sand the edges of the roadbed to smooth them up. I found a sheet of 100 grit open grid sanding pads made to sand sheetrock work excellently for this purpose.

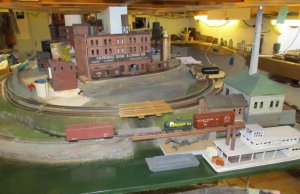

after I have sanded the roadbed I paint it with Latex paint I had the paint store mix me up a gallon of when it was on sale, to be a base scenery coat.. this way If I'm slow to get to ballasting, (and I will be ), my track will look beter because the cork won't show , and if the scenery comes up short of the raodbed, the plywood won't show, it will be gray paint. the outside track is the tail track to the wye, so trains can turn here, and back into State line, simplifying switching there, and relieving the need of using the turntable there unless the locomotive is staying there. The middle track will be for camp supply or to hold loaded log trains that are ready to go, or an empty log train waiting for it's turn on the loader. the inside track will be for the log lader, a narrow gauge track will be just above it to dump logs, and there may be a passing siding on the narrow gauge if I can fit it.

The other day I had the log loading rack from old Terrapin set up in the new, as of yet un named log reload area off the narrow gauge. I was thinking (not really the right word) that I could use it as is, and then I realized that with my old 8.5% grades a four car train was the norm. With an 3.3% ruling grade on the main, and a slightly steeper grade on the lead to the loading track, 8 car log trains may be possible, so room for four cars behind the loader would cause a major bottle neck, and some un necessary switching, in an area on the layout that will be too busy as is. so I cut some of the log bridge deck off the front of the assembly, and spliced it onto the back. I will run the back end of the cribbed loading deck, back to ground level, and add a short section of roadbed to allow another two or three extra cars , hopefully I'll be able to deal with loading a log log train big enough to make the new layout work, without Jacking up the Gizzard block with unnecessary switching.

Ready to cut the loading deck

ready to splice the loading deck bridge

One of The The Surry Parker will sit on the planked area, the short end is the lead to the rest of the siding, and the long lead will hold empty log cars that have passed under the Surry Parker .

this close up shows the rough edges you get separating Midwest cork roadbed. That rough edge can cause problems when ballasting, causing a rough edge, or worse, voids in the ballast just below those rough edges. I have found I get a lot better looking roadbed if I sand the edges of the roadbed to smooth them up. I found a sheet of 100 grit open grid sanding pads made to sand sheetrock work excellently for this purpose.

after I have sanded the roadbed I paint it with Latex paint I had the paint store mix me up a gallon of when it was on sale, to be a base scenery coat.. this way If I'm slow to get to ballasting, (and I will be ), my track will look beter because the cork won't show , and if the scenery comes up short of the raodbed, the plywood won't show, it will be gray paint. the outside track is the tail track to the wye, so trains can turn here, and back into State line, simplifying switching there, and relieving the need of using the turntable there unless the locomotive is staying there. The middle track will be for camp supply or to hold loaded log trains that are ready to go, or an empty log train waiting for it's turn on the loader. the inside track will be for the log lader, a narrow gauge track will be just above it to dump logs, and there may be a passing siding on the narrow gauge if I can fit it.

I got a blue point controller set up on the tail track switch for the wye. I will be able to run a cable to both aisles, so the wye will hopefully be fully operable from either side of the aisle. The switch to the log loading spur (the higher inside track) will be manual, so one will need to walk around the end of the peninsula a couple times if you are loading a log train, but that is an essential duty, and I should not make it too easy. the track on the log lading spur now extends as far as the end of the roadbed, where I will splice on the rebuilt loading log trestle from the Old Terrapin logging camp. I still not have named this camp. The other side of the wye is Perry's Gizzard, and the passing siding on the east wall is Ridgemont, so I'm out of old names to recycle.

the blue point controller on the tail track of the wye is wired as a reverser, so the tail tracks polarity will reverse when the switch is thrown, so it will always match up with whichever leg of the wye the switch is thrown for. I have installed a DPDT ground throw in the curved switch on the tail track, but it does not have a long enough throw to throw the switch. If it wire a hand laid switch I would modify the points to have less throw, but I'm not modifying a comercial curved switch, I need to find a DPDT switch that is larger or has a longer throw.

Below I'm transitioning from the flex track to the existing ties of the old cribbing and log bridge from Old Terrapin. I have stubs of flex track on the other end, so it will be relatively easy to spike down some code 83 rails. the inside track was originally laid with a KD spiker , and I put spikes in every tie, so I have a lot of tiny spikes to pull out before I lay the code 83. the spiker was not doing very well, and I quit using it. these full depth yellow poplar ties are hard as heck; and that may have been the problem. I will need to pull the spiker out and try it on ties cut from a softer wood, or thinner profile ties, also cut from a softer wood.

this is going to be fun!! I have to start work on the 5th of August, as the school year starts up, have already started some training, so I want to try to get things closer to operable soon if I can. I have done a lot of cleaning out construction debris in the aisles, and even cleaned up some of the debris and tools that had filtered down to the waterfront below the tail track ares

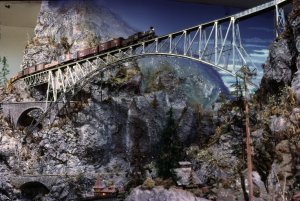

I have cleaned up the station area in Harlow , and the waterfront. the back side of Harlow is still buried under tools wood scraps, sawdust, and whatnot. as I get the standard gauged portion of the logging transfer fleshed out, I'll need to start working in the narrow gauge side, which will come off of a huge trestle that descends to the log transfer area, as the hege steel bridge ascends to the narrow gauge walk under (Duck under if you are taller the 6 foot three), that will carry the narrow gauge to the fourth shelf on the south wall, and hanging of the sloped ceiling on the west ceiling.

the blue point controller on the tail track of the wye is wired as a reverser, so the tail tracks polarity will reverse when the switch is thrown, so it will always match up with whichever leg of the wye the switch is thrown for. I have installed a DPDT ground throw in the curved switch on the tail track, but it does not have a long enough throw to throw the switch. If it wire a hand laid switch I would modify the points to have less throw, but I'm not modifying a comercial curved switch, I need to find a DPDT switch that is larger or has a longer throw.

Below I'm transitioning from the flex track to the existing ties of the old cribbing and log bridge from Old Terrapin. I have stubs of flex track on the other end, so it will be relatively easy to spike down some code 83 rails. the inside track was originally laid with a KD spiker , and I put spikes in every tie, so I have a lot of tiny spikes to pull out before I lay the code 83. the spiker was not doing very well, and I quit using it. these full depth yellow poplar ties are hard as heck; and that may have been the problem. I will need to pull the spiker out and try it on ties cut from a softer wood, or thinner profile ties, also cut from a softer wood.

this is going to be fun!! I have to start work on the 5th of August, as the school year starts up, have already started some training, so I want to try to get things closer to operable soon if I can. I have done a lot of cleaning out construction debris in the aisles, and even cleaned up some of the debris and tools that had filtered down to the waterfront below the tail track ares

I have cleaned up the station area in Harlow , and the waterfront. the back side of Harlow is still buried under tools wood scraps, sawdust, and whatnot. as I get the standard gauged portion of the logging transfer fleshed out, I'll need to start working in the narrow gauge side, which will come off of a huge trestle that descends to the log transfer area, as the hege steel bridge ascends to the narrow gauge walk under (Duck under if you are taller the 6 foot three), that will carry the narrow gauge to the fourth shelf on the south wall, and hanging of the sloped ceiling on the west ceiling.

working in the roadbed around the Gizzard high bridge. and checking things out. I need another steel support on the long span. have the parts painted, and just have to assemble them. this will add some more support, and get what is now the center support out of the middle of the creek. there will be a tall outcropping in the middle of the wye, and I may put a short masonry support on it in the middle of the short span. I have the risers in for the narrow gauge sub roadbed . and am repurposing some of the old narrow gauge sub roadbed ( with homabed road bed already in place ) from the old ridgemont area. It will be kind of chopped up, but this is at about six feet two inches above the floor, someone is going to have to be standing on a ladder or a stool to see the roadbed at all.

behind the bridge you can see a descending line, that is the bridge deck leading to the log reload off the narrow gauge. it will get a combination trestle log bridge built under it at some time.

with the exception of the sidings to the water powered sawmill, all the standard gauge tracks are in place on the upper level of the central peninsula. I think I will work to get some rudimentary scenery in soon, around the log reloading area, so I can safely get some of my logging machinery out of the boxes they are stored in.

behind the bridge you can see a descending line, that is the bridge deck leading to the log reload off the narrow gauge. it will get a combination trestle log bridge built under it at some time.

with the exception of the sidings to the water powered sawmill, all the standard gauge tracks are in place on the upper level of the central peninsula. I think I will work to get some rudimentary scenery in soon, around the log reloading area, so I can safely get some of my logging machinery out of the boxes they are stored in.

I soldered the loader tail track bridge deck in between some flex track. there are only two short sections of standard gauge track left to install on the upper deck. all the subroadbed, and some of the roadbed is down, but it doesn't go anywhere yet, as the walk under to the top shelf isn't done, nor is the long shelf hanging off the sloped ceiling to get the narrow gauge from State line up to the back end of the central peninsula. the tracks are down on the bridges though, and there may be as much track on the bridges as there is off of them.

The loader's tail track is directly over the Gorre County Courthouse.

getting close on the track, it is time to start playing with the scenery. everything else has been work, this is fun ! Cardboard strips hot glued to the bottom of the sub roadbed. gluing them to the sides does not leave enough clearance if you do thick scenery, as I tend to do.

Here I have started to bend the cardboard strips into the shape of the cliff that will help make a view block between the log transfer scene, and the wye, which is a few inches away. I will need to work to get this shape a little farther from the track. I will be covering this with white glue soaked handi wipes, and then plaster that I will carve rocks into. I like to put the plaster on thick. this would be good if it were the outside edge of the finished scenery, but I'll want to put an inch of plaster on top of this, and that would push it too close to the tracks.

The loader track will be supported on cribbing, or a log trestle. I nave not done land forms in front of the loading track, as I want to but a stream down in a little ravine, and that is going to take a lot of work, but it will add some depth to the scenery, and a lot of interest to the semi permanent camp that I'll build up here. I'm thinking of calling this place Sunburst, after a Champion Fiber operation.

The loader's tail track is directly over the Gorre County Courthouse.

getting close on the track, it is time to start playing with the scenery. everything else has been work, this is fun ! Cardboard strips hot glued to the bottom of the sub roadbed. gluing them to the sides does not leave enough clearance if you do thick scenery, as I tend to do.

Here I have started to bend the cardboard strips into the shape of the cliff that will help make a view block between the log transfer scene, and the wye, which is a few inches away. I will need to work to get this shape a little farther from the track. I will be covering this with white glue soaked handi wipes, and then plaster that I will carve rocks into. I like to put the plaster on thick. this would be good if it were the outside edge of the finished scenery, but I'll want to put an inch of plaster on top of this, and that would push it too close to the tracks.

The loader track will be supported on cribbing, or a log trestle. I nave not done land forms in front of the loading track, as I want to but a stream down in a little ravine, and that is going to take a lot of work, but it will add some depth to the scenery, and a lot of interest to the semi permanent camp that I'll build up here. I'm thinking of calling this place Sunburst, after a Champion Fiber operation.

Zathros, the old logging camp was @ Terrapin, but On this installment of my RR Terrapin will be on the lowest level,,@ the return loop, as properly fit the Grateful Dead lyrics " Terrapin: I can't figure out. Terrapin, if it's the end or beginning, Terrapin, but the train has put it's brakes on, Terrapin, and the whistle is screaming.

On the Terrapin station album, they used art work derived from a photo of an Ho scale model kit. it was a model of the Mount Princeton Colorado station , and they started the artwork for the album cover from a photo of a diorama that was used in the MR review of the kit. I bought one of the kits. and will be using it in my new Terrapin, just like it was in my old Terrapin.

In some of the photos the loader is crooked. The track did not want to lay flat under it, but there was a crack between the ries and one of the split logs on the landing, I was able to run a sheetrock screw through the hole, and level up the track the loader sets on. I'll have to come back and set a barrel or a crate on the screw head so it doesn't show in any closeups.

Nelson

On the Terrapin station album, they used art work derived from a photo of an Ho scale model kit. it was a model of the Mount Princeton Colorado station , and they started the artwork for the album cover from a photo of a diorama that was used in the MR review of the kit. I bought one of the kits. and will be using it in my new Terrapin, just like it was in my old Terrapin.

In some of the photos the loader is crooked. The track did not want to lay flat under it, but there was a crack between the ries and one of the split logs on the landing, I was able to run a sheetrock screw through the hole, and level up the track the loader sets on. I'll have to come back and set a barrel or a crate on the screw head so it doesn't show in any closeups.

Nelson

Last edited:

I like seeing the loader "in action." Correct me if wrong but I believe that is exactly how the prototype moved log cars through.

Interesting bit of Logging RR history I came across recently is that empty log cars did not sit around at the landings. The steamer that brought the empties hauled em' loaded. Would explain the popularity of the loaders like the Surrey Parker. They loaded up the trains fairly quickly.

Doc Tom

Interesting bit of Logging RR history I came across recently is that empty log cars did not sit around at the landings. The steamer that brought the empties hauled em' loaded. Would explain the popularity of the loaders like the Surrey Parker. They loaded up the trains fairly quickly.

Doc Tom

Thats right Tom, a string of empties would be shoved under the loader, with one in place to be loaded, when it was full , the string would be advanced one car at a time until the whole train was full. I had to make modifications to the landing to fit the larger trains that are possible on my rebuild. If the road locomotive picked up a loaded train as soon as it got there and dropped off the empties then you would need a bunch more log cars, and a switch engine to live in the camp full time. That would get expensive quick. I was originally thinking I'd run this camp with a switch engine, but now I'm not so sure. the number of cars I can load in any given day would be dependant on what the narrow gauge could deliver. Likely I'll run two trains a day from this camp to the sawmill, possibly with a third, where the empties would go up here in the late afternoon, the crew would spend the night on the mountain. and head down in the early AM. Those details I'll have to work out later, and it may depend on how many operators are available for me to traumatize.

Good thinking Bill. I have not read or heard of a switcher engine hanging around a log landing shuffling cars around like they might do at coal mine yard. Like you report there just not enough room and the costs would be prohibitive. I like the idea of overnight stay for a crew. They would probably enjoy the fresh night air high in the mountains.

Looking forward to operations on your new layout.

Dr Tom

Looking forward to operations on your new layout.

Dr Tom

I traded some of my dad's old stuff for some old time equipment The long coach was missing some trucks, and the truss was damaged on the back side. I put pads on it, so it would be easy to add body mounted couplers to it if I want to put it into service, but for now, it has some leftover trucks on it, and is painted up to use as crew quarters at the landing. The Mantua combine will serve as storage and the office, with more crew quarters in the Mantua coach, which is warped up some on the back side.

there were three Mantua/Tyco 1880 combines in the stuff I traded for. I just got done putting three of them in caboose service. I cut two of them in two, and rearainged the pieces to make a Baggage car and a coach, which, with the remaining combine, makes a nice little passenger train.

there were three Mantua/Tyco 1880 combines in the stuff I traded for. I just got done putting three of them in caboose service. I cut two of them in two, and rearainged the pieces to make a Baggage car and a coach, which, with the remaining combine, makes a nice little passenger train.

Hi Bill. Am I seeing old "C&S" flats in the first picture? If so, good to see them in action again. That SP loader is working overtime to get the logs out.

Like the crew cars too. Doc Tom

Like the crew cars too. Doc Tom