All you need for the educational license is a kid who is a student? Let's say, when one of my children goes to university (or school?) I show rhino vendor that proof and can get it?Blender is an excellent program. If I didn't have so many years vested in Rhino, and so few left in life, I might learn it. I just picked up Rhino 8 as my Godson got it for the educational price. He wants me to teach him. $195, if you have a student buy it, and it's the same as the full version, it is the full version, just made affordable for students. We're all students of some soft.

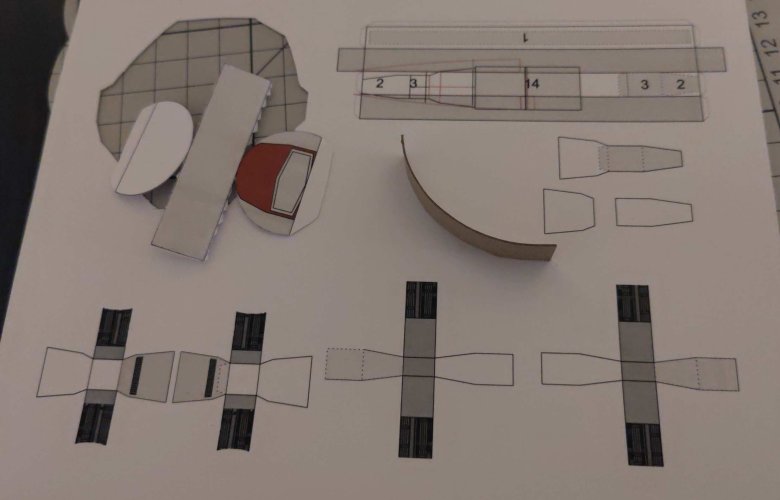

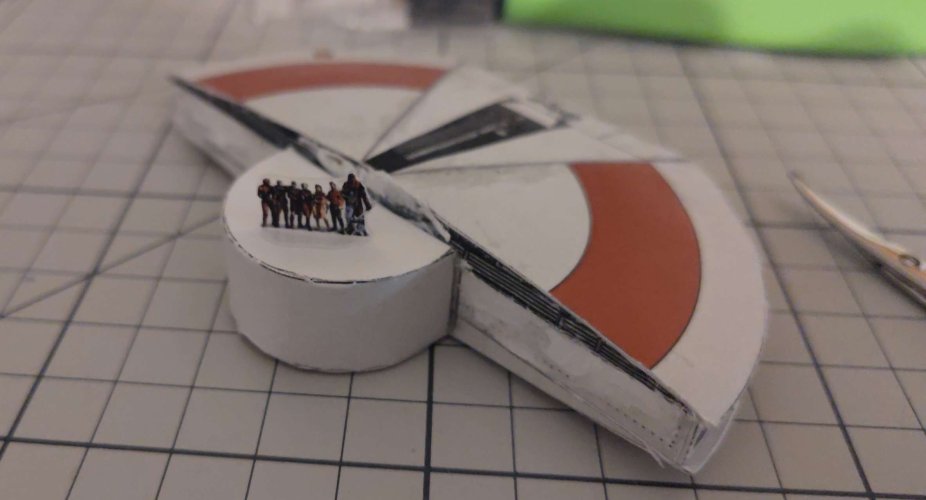

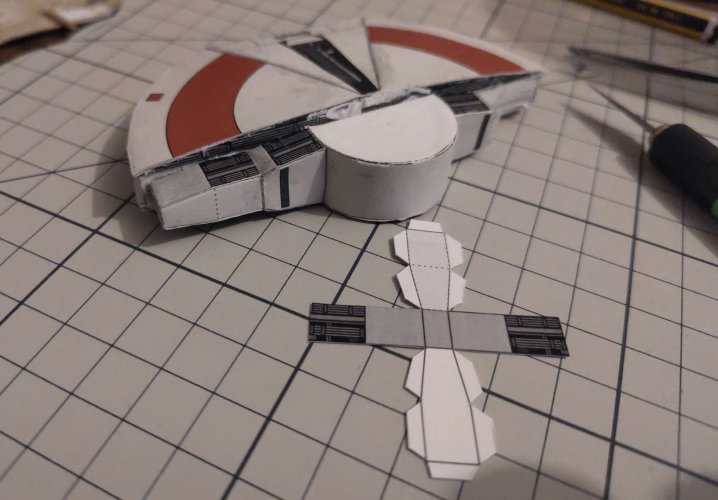

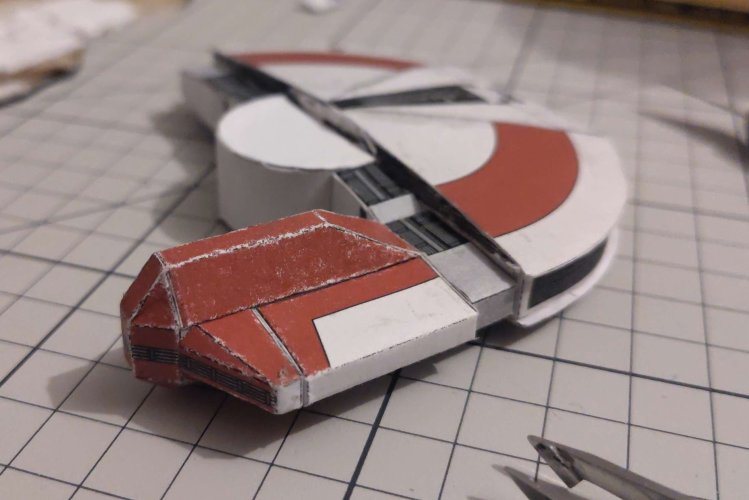

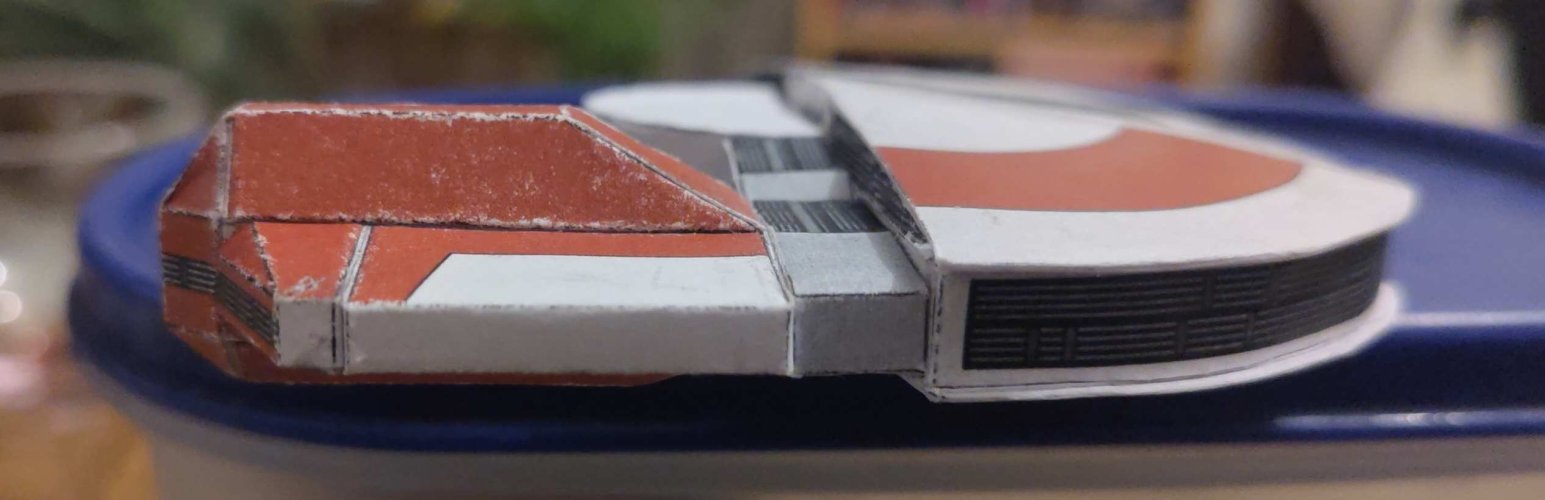

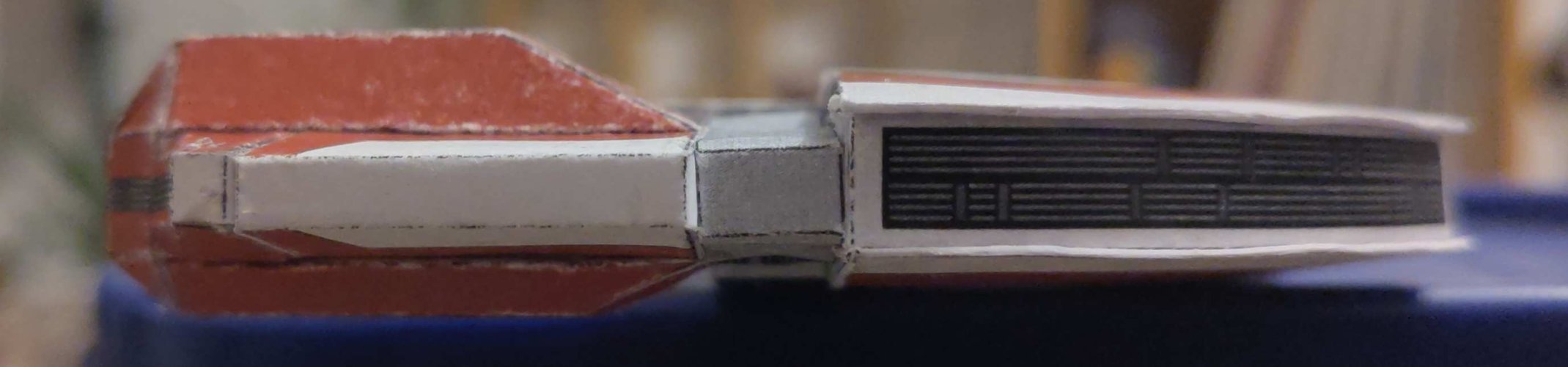

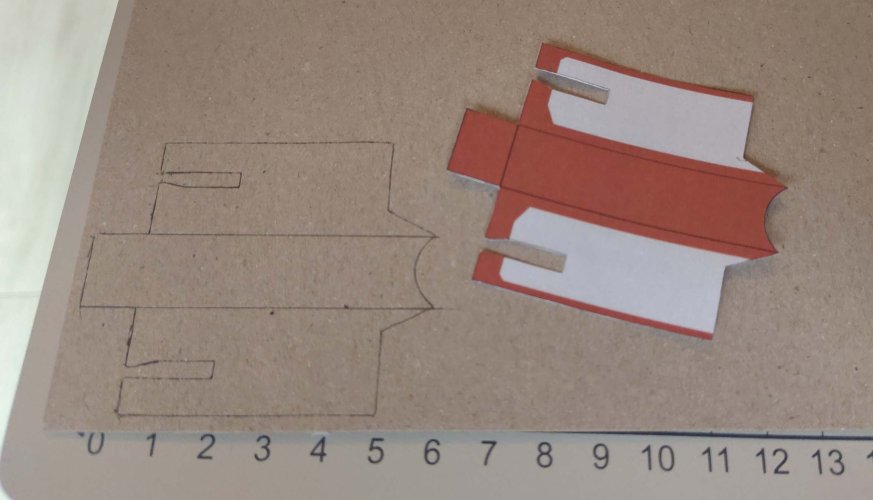

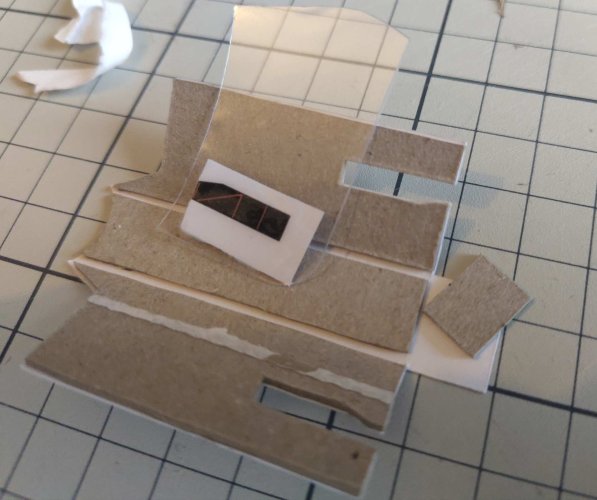

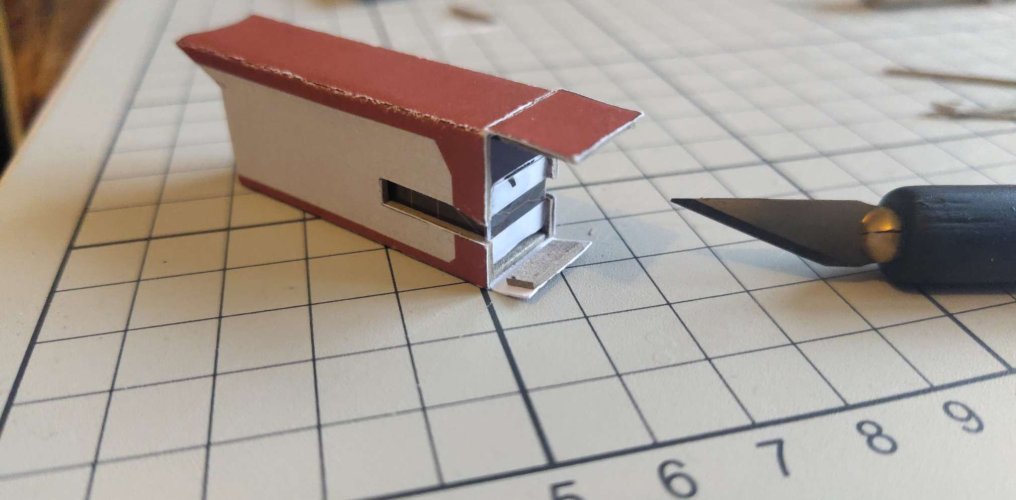

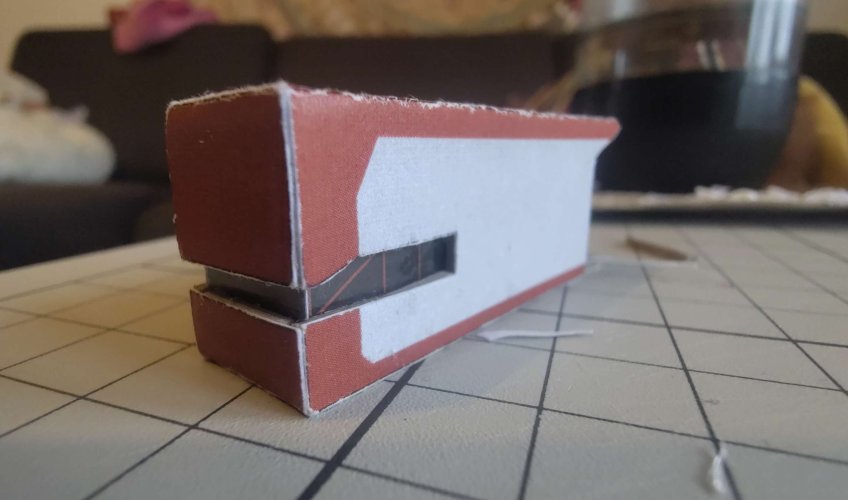

Your model is coming out great!

Does it also work for german students?