Hi,

It's been awhile. This is a design I originally made from cardstock, but I have always wanted an actual working version. I have really been inspired by RobotHut, who has made several versions of all of the drones, some full scale. The challenge for me has been how to achieve the walking mechanism simply, but also have that distinct gait and movements of these guys. There have been so many awesome builds of the drones over the years, so I don't really know if I'll add to that list, but, as most of my projects are, I just can't not do it.

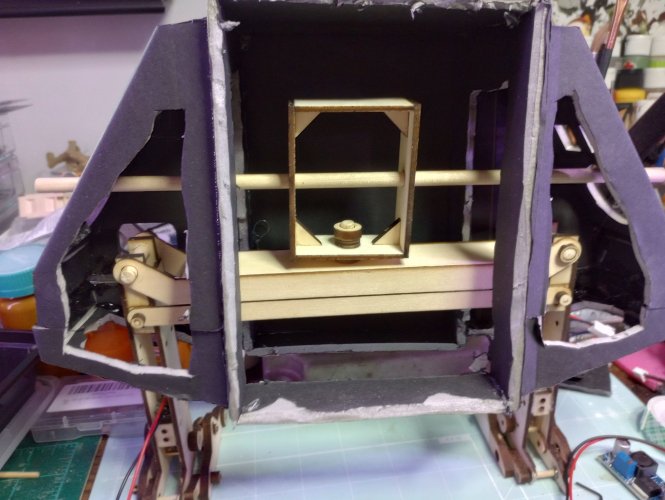

The first thing I decided was to fake it. The walking mechanism that is. I'm sure that there are ways to use some sort of bipedal mechanism that actually does as the movie portrays, but that's way over my head. I can, however fake the motivating mechanics with two triangular four bar mechanisms, one in each foot, and use a telescoping "shell" on each leg that will be like a hollow pants leg of sorts. Although there will actually be two feet on the ground at all times, it will mimic the the kind of weight tossing gait of the original props.

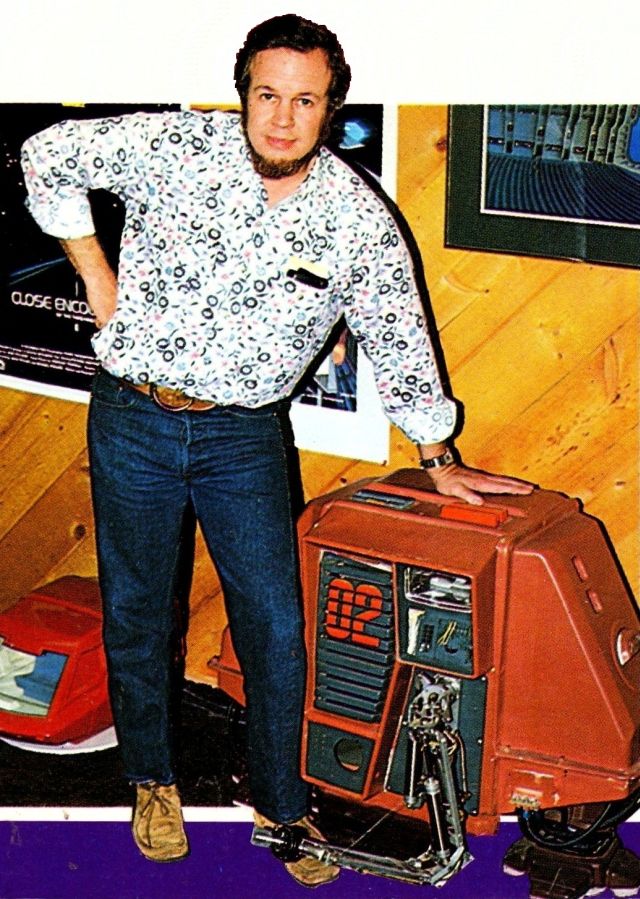

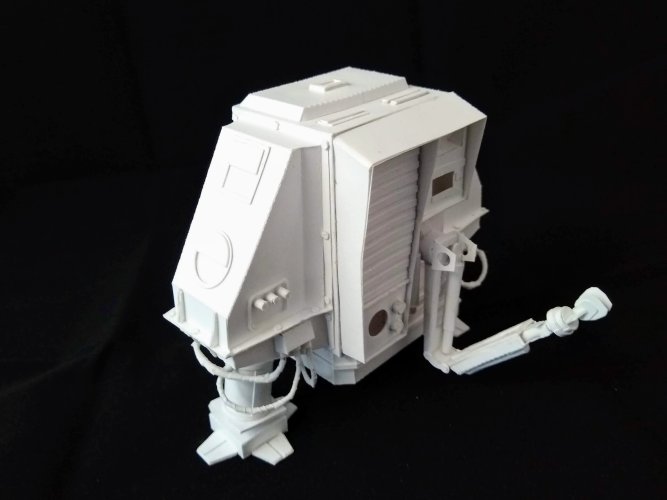

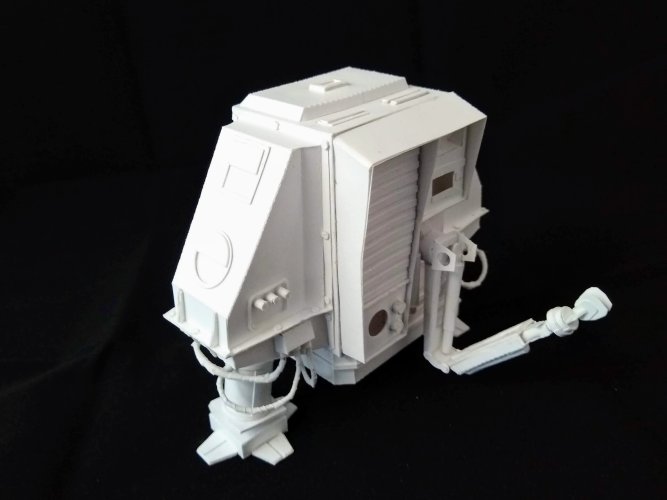

I've been working on this for years, but more so over the last year. I'll post some catchup project photos and videos, but here is a pic of the card model design:

That's about all I can squeeze out tonight.

It's been awhile. This is a design I originally made from cardstock, but I have always wanted an actual working version. I have really been inspired by RobotHut, who has made several versions of all of the drones, some full scale. The challenge for me has been how to achieve the walking mechanism simply, but also have that distinct gait and movements of these guys. There have been so many awesome builds of the drones over the years, so I don't really know if I'll add to that list, but, as most of my projects are, I just can't not do it.

The first thing I decided was to fake it. The walking mechanism that is. I'm sure that there are ways to use some sort of bipedal mechanism that actually does as the movie portrays, but that's way over my head. I can, however fake the motivating mechanics with two triangular four bar mechanisms, one in each foot, and use a telescoping "shell" on each leg that will be like a hollow pants leg of sorts. Although there will actually be two feet on the ground at all times, it will mimic the the kind of weight tossing gait of the original props.

I've been working on this for years, but more so over the last year. I'll post some catchup project photos and videos, but here is a pic of the card model design:

That's about all I can squeeze out tonight.